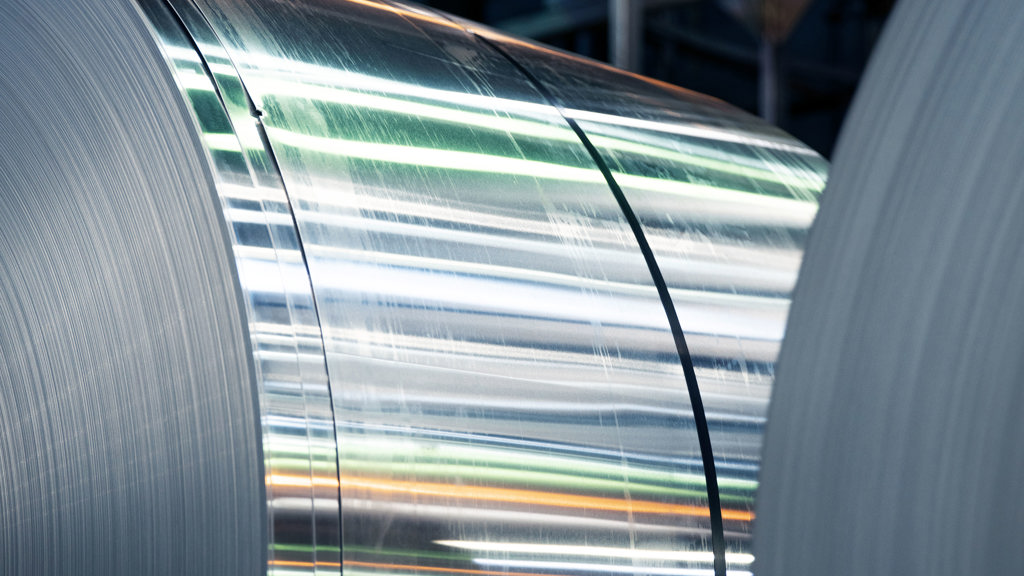

Industrial applications & Consumer Goods Aluminium – the perfect material for trade and industry

From the newspaper in your hands to the heat exchanger in your car and even the tea lights in your living room: for every application, we have a solution. Together with you, we can implement challenging projects with enthusiasm and passion.

Contact us Let’s create your next aluminium solution

Are you developing durable consumer goods or complex industrial applications? Our specialists support you from first concept to final implementation – with tailored alloys, technical expertise and coil configurations that fit your process. If you’re aiming for efficiency, durability and design precision, contact us.

A highlight in our portfolio: Sustainable tealights We roll starting materials and recycle used tealight holders

Tealights create an intimate ambiance, exude warmth and can be found in almost every household. With our aluminium foil, we ensure that they can be used safely. Our finely-tuned process includes the option of customized lubrication and guarantees optimal mechanical processing.

At our Norwegian plant in Holmestrand, we have a long tradition of manufacturing tailor-made solutions with the lowest tolerances, which are also recyclable and exceptionally economical in material use. For our final products, we use high-quality material such as synthetic FDA-approved vegan lubricant.

As one of the very first suppliers, we're already traveling around in millions of cars.

We develop customized solutions for all aspects of heat exchangers – including industrial applications.

Heat exchangers don't just play a major role in the automotive sector; the technology is also applied in many other sectors. At Speira, we produce innovative pre-materials for heat exchangers made of aluminium, which feature high strength and corrosion resistance - and also offer opportunities for weight reduction through targeted refinement of alloys.

Our industry-leading center for research and development produces customized solutions and technologies for a wide range of industries. We produce strips and sheets for heat exchangers for the automotive industry, in air conditioning, cooling and heating, and other areas.

An alloy for any need

We live in a world that feeds us information on a daily basis - above all, print media are still of huge importance here. That makes it all the more important to produce the very best prints. Our material makes this possible, thanks to its excellent processing and surface quality.

Our materials allow maximum flexibility for every application area

Every day we have them in our hands. They inform us or provide relaxation. Whether it's the newspaper in the morning or a good book in the evening - our alloys enable the best printing results.

We use our own custom-developed HPSplus process to produce an optimized and homogeneous surface. This results in lithographic ribbons for offset printing plates that have the highest smoothness and ideal processing properties. In this way, we've created a processing chain for manufacturers of offset printing plates that achieves increased throughput coupled with enhanced energy efficiency and improved product quality.

In our research and development as well as in our lithography centers, we exploit the advantages of the metal, producing cutting-edge high-performance alloys with energy-saving processing. This yields the most stringent, uniform flatness while meeting surface tolerances. All our products are suitable for mechanical or electrochemical buffing. The thickness range extends from 0.1-0.5 mm in widths of up to 1650 mm. And since we're always looking for ways to further improve, we've launched our latest alloy HA1052B in hardness grades H18 and H19, a product boasting even more ideal properties.

Contact us Discover aluminium solutions that deliver

Whether you’re developing a new product or optimising an existing one, our experts are here to support you – with the right materials, technical insight and production-ready coil design. Get in touch with us today.