Aluminium rolled products Quality without compromise

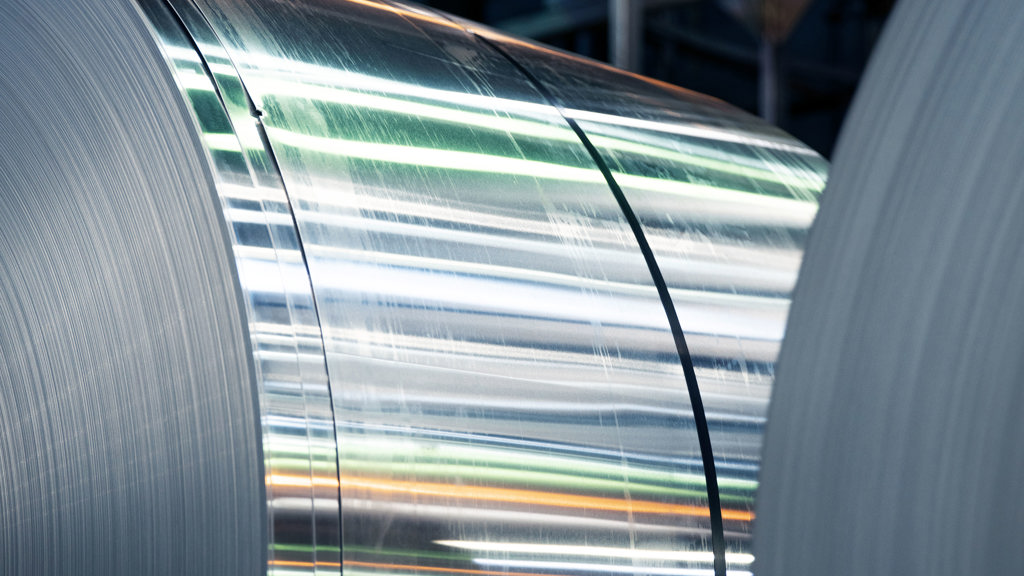

As a leading European aluminium rolling and recycling company, we are redefining the boundaries of aluminium rolled products. With advanced manufacturing processes and innovative surface finishing, we produce high-quality, and recyclable rolled products. With aluminium plates, aluminium coils as well as aluminium sheets and strips, we deliver tailor-made solutions for your industry.

Speira: Advanced rolled products for a wide range of applications

In connection with the increasing global demand for aluminium rolled products, we rely on innovative processes to not only meet the requirements of the market, but to actively help shape it with economical, sustainable and contemporary solutions.

Speira produces rolled products and recycles aluminium at a total of eleven locations in Germany and Norway. Our joint venture Alunorf is the largest aluminium rolling mill in Europe, while we operate the largest refining plant in Europe in Grevenbroich. With many years of experience and the highest level of expertise, we ensure that we produce high-quality aluminium rolled products for our customers in global industries such as automotive, packaging, printing, mechanical engineering, building and construction.

We are well on the way to setting new industry standards in sustainable aluminium rolled products based on first-class rolling and recycling capabilities.

Production of aluminium rolled products

Speira's aluminium rolled products are made from recycled metal and primary aluminium. Large aluminium ingots are cast from the liquid metal, which we then process into aluminium rolled products such as sheets, strips, coils or plates.

Before and during hot rolling, the metal is heated to a temperature above the so-called recrystallization temperature. This method brings the metal to a state in which it is easy to form and therefore easy to roll. During subsequent cold rolling, the material is further processed into thin strips and becomes stronger through cold forming. Intermediate annealing at temperatures between 300 and 400 °C is sometimes necessary to precisely adjust the strength. If the end product is to be easily formable again, soft or condition annealing is carried out at precisely defined temperatures after rolling.

In our rolling mills, electrically operated rollers are mounted in stable stands. In duo stands, the lower roll is fixed, and the upper roll is adjustable. Quarto stands use additional back-up rolls to stabilize the work rolls with the high rolling forces of up to several 1000 tons. Reversing stands in hot rolling mills allow the material to be rolled both forwards and backwards.

Together with the so-called finishing stands, they are part of hot rolling mills that can be several hundred meters long and enable a very high production capacity. The result, wound onto a roll and cut to the required final width, is the semi-finished product that we supply to our customers. They in turn produce beverage cans, façade cladding, roller shutters, roofing, components and much more. If the aluminium rolled products are to be further refined, they are sent for surface treatment before delivery.

Surface processing of rolled aluminium

Processes such as grinding, brushing, polishing and anodizing are used to finish aluminium rolled products. Anodizing in particular, an electrochemical process, strengthens the natural oxide layer of the aluminium and thus creates a particularly robust surface. This not only provides greater protection, but also gives the material an attractive appearance.

When it comes to pre-painted aluminium rolled products, we have the highest level of expertise from over 30 years of experience. Coil coating in our production lines is a finishing process that we have mastered to perfection with our special expertise.

Our rolling mills for the production of aluminium rolled products

Speira's headquarters are located in Grevenbroich – Europe's largest aluminium finishing plant for sophisticated aluminium rolled products. The production facility, which is centrally located to our many other sites, produces more than 600,000 tons of aluminium rolled products per year.

Our joint venture Alunorf in Neuss is a true powerhouse, turning over around 1.5 million tons of production volume per year. Here we have two hot rolling mills and five cold rolling mills for customized aluminium rolled products.

Our plant in Hamburg is a real allrounder and is also our most important logistics location in Europe. More than 165,000 tons of aluminium strip are produced on site for a wide range of applications.

The Holmestrand plant is located in Norway, south of Oslo. An innovation center for aluminium recycling and the most sustainable aluminium rolling mill in Europe. Every year, the employees produce almost 100,000 tons of aluminium rolled products with an average carbon footprint of less than 5.5 kg CO2/kg Al. With the coating plant in Holmestrand, which has a capacity of more than 50kt, we can meet almost all of our customers' highly specific requirements.

Holmestrand is complemented by our plant in Karmøy, which produces more than 90,000 tons of rolled aluminium with low CO2 emissions of less than 5.5 tons per ton of aluminium.

Versatile areas of application for aluminium rolled products

Our aluminium rolled products can be processed in a wide range of markets and products and impress with their outstanding material properties. Starting with their high strength and excellent corrosion resistance through to their lightness and easy formability.

Our product portfolio of aluminium rolled products offers a wide range of solutions:

- Interior and exterior components as well as electromobility in vehicle construction

- aluminium facades, window frames and shading, doors and roofing made of aluminium in the field of architecture and construction

- Aluminium packaging for food and pharmaceutical products

- Aluminium beverage cans

- Shipbuilding, transportation and traffic

- Battery systems

- Special industrial applications and consumer goods

You can reach us in writing Your contact to Speira

Speira stands for high-quality aluminium solutions based on research, development and technical expertise. Our experienced team develops semi-finished products for various applications that are tailored to your requirements.

Of course, we are always available to advise you on all aspects of aluminium rolled products and work with you to design individual solutions. Please feel free to contact us via the contact form.